Add to Cart

CW118C(CuTeP-2.1546) Tellurium Copper Alloy Used in Electronics and Electrical Engineering

Product Normal Description:

Product Name: Tellurium copper alloy

Grade: CW118C (CuTeP-2.1546)

Size: according customer's requirement

State: H02 H04

Typical Application: Electrical

Product Brand: CUBERYLLIUM®

Application Area of CW118C(CuTeP-2.1546) Tellurium Copper Alloy:

The alloy is mainly used for: high conductivity, high conductivity, corrosion-resistant precision electronic and electrical components, advanced mechanical and electrical components, forgings and thread cutting parts, plumbing fittings, electrical contact parts, welding and cutting advanced gun nozzle, aerospace connectors, new energy automotive connectors, motor and switching parts. Products can be processed into plates, sheets, rods, wires, pipes and other profiles and various profiled materials. It is widely used in high voltage and high current connection because of its excellent arc resistance, welding resistance and viscosity resistance, high and low temperature performance, low insertion loss, high conductivity, low thermal EMF after silver plating and strong anti-interference ability. Connector industry.

Tipical Application of Tellurium-bearing Copper Alloy CuTeP-2.1546:

Gas cutting nozzles

High-speed automatic screw machines

Electrical Switches on power semiconductors

Welding Torch tips

Transformer & Circuit-breaker terminals

Fasteners

Production of hot forged products

Chemical Composition of CW118C(CuTeP-2.1546) Tellurium Copper Alloy:

| CUBERYLLIUM® Brand | ASTM | Tellurium | Phosphorus | Copper | |||

| Cuberyllium-C145 | C14500 | 0.40-0.70% | 0.004-0.012% | 99.2% | |||

Fabrication of CW118C(CuTeP-2.1546) Tellurium Copper Alloy:

| Joining Technique | Suitability |

| Brazing | Good |

| Butt Weld | Fair |

| Capacity for Being Cold Worked | Good |

| Capacity for Being Hot Formed | Good |

| Coated Metal Arc Welding | Not Recommended |

| Forgeability Rating | 65 |

| Gas Sheilded Arc Welding | Fair |

| Machinability rating | 85 |

| Oxyacetylene Welding | Fair |

| Seam Weld | Not Recommended |

| Soldering | Excellent |

| Spot Weld | Not Recommended |

Shape Available of CW118C(CuTeP-2.1546) Tellurium Copper Alloy:

| Shape | Condition | Size |

| Straight Round Rod/Wire | Hard/Half Hard | Φ2-15mm |

| Straight Round Rod | Hard/Half Hard | Φ3-90mm |

| Flat Bars/Plates/Sheets | Hard/Half Hard | Φ5-100mm |

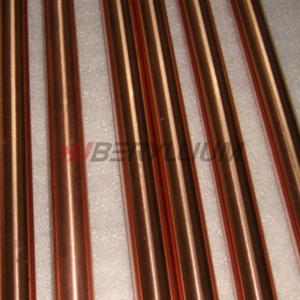

Product Photo:

FAQ:

1; HOW LONG IS YOUR DELIVERY TIME?

Generally the delivery time should be 2-3 days if the goods is in stock.

If it is customized, the delivery time will be around 10-15 working days, depends on the trial quantity.

2; DO YOU PROVIDE SAMPLES? IS IT FREE OR EXTRA?

Yes, we could offer the samples for free charge if the sample in stock, and not be customized, but we don't pay the air cost.

3; WHAT IS YOUR MAIN CUSTOMER AND HOW ABOUT YOUR PRODUCT QUALITY?

Our producs are exported to the countries all over the world. Our quality is very good, we could accept the SGS Inspection, but the charge for the inspection should be paid by customer.